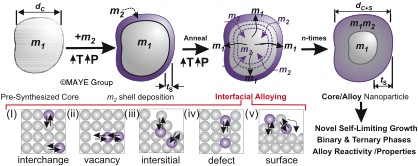

We recently began to explore a fresh approach towards fabricating nanomaterials with an alloy interface. As shown in the schematic above, our approach starts with a pre-synthesized nanoparticle (NP) core, of which, we can precisely tailor size, shape, and composition. Next, we deposit a nanometer thin shell of a second metal. This step is crucial and we have spent a lot of time perfecting shell deposition. Next, the core/shell NP is heated to elevated temperatures and pressures, upon which, the core and shell metals start to diffusion into one another, thus forming a “core/alloy” nanoparticle.

Led by Dr. Peter Njoki and graduate student Wenjie Wu, we have been able to create a number of exciting morphologies and compositions recently, as well as discovered some new phenomena. Shown to the right is a typical HRTEM image of one of these core/alloy NPs, as you can see, the particles are highly uniform, and in this case are about ~15 nm in diameter. Another interesting aspect to this system is how to determine the precise composition at the interface, as well as learn more insights into the core-shell diffusion? For this, we turned to modeling the optical properties of these metallic nanoparticles, a phenomena known as surface plasmon resonance (SPR). By performing extensive modeling of the core/shell and core/alloy NPs using discrete dipole approximation (DDA), we have been able to correlate our observations with precise alloy shell compositions, as well as shell thickness. Many futher studies are underway, but recent results can be found at JACS, Chem. Commun., and J. Phys.Chem.C.